Why Accurate Box Dimensions Matter

In the packaging industry, getting the dimensions right is critical. Whether you’re shipping products, designing custom handle boxes, or organising storage, accuracy ensures everything fits just as it should. Incorrect measurements lead to wasted material, damaged goods, and additional costs. When it comes to custom packaging, particularly custom handle boxes used in retail and branding, precision guarantees the box serves its purpose perfectly—protecting the product while delivering visual appeal.

Understanding the Basics of Box Measurements

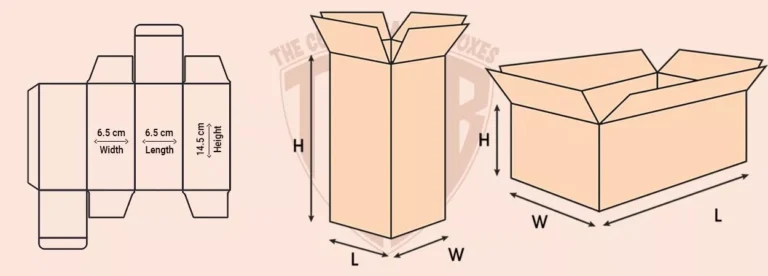

Before diving into measuring techniques, it’s essential to understand the three core dimensions of a box: length, width, and height. These are always measured from the inside of the box. The industry-standard order is Length x Width x Height (L x W x H). Length is the longest side of the opening, width is the shorter side, and height is the distance from the top of the opening to the bottom of the box.

Tools You Need for Measuring

To measure any box accurately, all you need is a reliable measuring tape or a ruler, a flat surface, and a notepad or device to record your measurements. For boxes with unique shapes, callipers can be useful for internal dimensions. Always make sure your measuring tools are not worn out or bent, as this could skew the results.

Step-by-Step Guide to Measuring a Box

Start with the length. Place the box on a flat surface, and measure the longest open side from one end to the other. This is your length. Next, measure the width, which is the shorter open side perpendicular to the length. Finally, measure the height from the base of the box to the top edge. Be sure to take internal measurements, especially for custom handle boxes, because the external dimensions can include added elements like the handle or extra layers that do not affect the internal capacity.

Measuring for Custom Handle Boxes

Custom handle boxes are not your average packaging solution. They combine functionality and branding, so their dimensions impact not only their practical use but also their aesthetic value. When measuring a custom handle box, pay close attention to the area where the handle is incorporated. For die-cut handles, factor in the depth and position. If it’s a plastic or rope handle, measure its length and placement relative to the top edges. These details affect comfort, grip strength, and visual balance. Always account for how the handle alters the top closure when closed.

Interior vs Exterior Dimensions

For custom packaging, especially when fitting specific products, interior measurements are vital. These tell you exactly how much space is inside the box. However, if you’re arranging boxes in shelving or display racks, exterior measurements help you understand how much space the entire package will occupy. When ordering custom handle boxes, make sure to specify whether you need interior or exterior dimensions to avoid miscommunication with the manufacturer.

Considering Material Thickness

The thickness of the box material can significantly affect your dimensions, especially when scaling designs or working with multiple layers. Cardboard, kraft, corrugated, and rigid board materials all vary in thickness. A box made from thick corrugated cardboard may have a smaller internal volume compared to one made from thinner kraft paper, even if the outer measurements are the same. When working on custom handle boxes, consider both functional space and the durability offered by the material.

Measuring Odd-Shaped Boxes

Not all boxes are perfect rectangles. Some have triangular flaps, curved edges, or multiple compartments. In such cases, divide the box into measurable sections. For example, a triangular top can be measured separately from the rectangular base. If your box has compartments, measure each one independently, especially when designing custom inserts for custom handle boxes. The more precise your breakdown, the better the final packaging fit and feel.

Why Custom Handle Boxes Need Precision

Custom handle boxes often serve as both a carrier and a brand ambassador. From bakeries and fashion outlets to tech gadget packaging, they’re expected to hold weight, present well, and open easily. If the handle is misaligned or the box lacks structural balance, it compromises the user experience. Precision in dimensions ensures the handle is functional, the structure is sound, and the design remains visually cohesive. Customers notice these details, and brands build trust through consistent quality.

Communicating Dimensions to Packaging Partners

When you’re sending box specs to a printer or packaging supplier, always list the dimensions in the proper order: Length x Width x Height. Mention if the dimensions are interior or exterior and clarify handle placement. It helps to include a simple sketch or diagram, especially when ordering custom handle boxes. Being clear and consistent prevents delays and ensures you get exactly what you envisioned.

Using Prototypes for Confirmation

Before placing large orders, ask for a prototype. It’s the most practical way to confirm dimensions, check the handle’s comfort, and test how the product fits inside. Prototypes let you assess weight distribution, ease of carrying, and aesthetic alignment. For custom handle boxes, where functionality and presentation go hand-in-hand, this step is crucial.

Measuring for Inserts and Accessories

Many custom handle boxes come with internal inserts to hold products securely. These could be foam holders, cardboard dividers, or moulded trays. To measure for these, start with the dimensions of the product they’ll hold, then measure the interior of the box. Leave room for easy insertion and removal, especially if the product is delicate or has an unusual shape. Don’t forget to measure vertically if the insert will elevate the product closer to the top for presentation.

Shipping and Storage Considerations

If your custom handle boxes are shipped flat and assembled later, include fold line measurements, and total unfolded dimensions. This helps with estimating storage space and shipping costs. Also, measure the box when it’s assembled to ensure the structure maintains its dimensions. Keep in mind that overly tight folds or misaligned cuts can distort final dimensions slightly, especially with bulk orders.

Common Mistakes to Avoid

One frequent mistake is assuming the height is always the vertical side. If the box opens from the side or has a flap that changes the opening direction, the height might not be the vertical measurement. Another error is measuring from the outside, which includes flaps and layers that don’t affect internal capacity. Always remove padding, lids, or flaps before measuring the inner dimensions. Lastly, forgetting to measure with the product in mind can lead to designs that look good but don’t perform well.

Industry Applications for Custom Handle Boxes

Custom handle boxes are used across industries—food packaging, cosmetics, promotional kits, retail items, and more. Each sector has specific measurement needs. In cosmetics, dimensions must fit multiple small products snugly. In food, there must be room for containers and airflow. For retail, visual symmetry and easy handling are priorities. Accurate measurements help brands meet their industry standards without compromising style or safety.

Enhancing User Experience Through Accurate Sizing

Imagine carrying a box that’s too wide, awkwardly tall, or flimsy because the dimensions are off. It affects not just usability but perception. Accurate sizing ensures comfort when held, easy stacking, neat storage, and better shelf presence. When users find the box easy to carry, reuse, or recycle, the brand earns extra points. With custom handle boxes, your goal is to combine utility with a refined look—and measurements are the starting point.

Conclusion

Measuring box dimensions might seem like a basic task, but when done right, it saves money, protects your product, and enhances your brand image. Whether you’re dealing with simple packaging or high-end custom handle boxes, accurate dimensions make the difference between a good packaging experience and a great one. By mastering these measuring techniques and communicating them clearly, you position your brand for consistency, quality, and customer satisfaction. Always measure smart, test often, and prioritise precision—because in the world of packaging, every millimetre counts.

Enjoyed this? Share this post with fellow fans and influencers, and be sure to check back regularly for the latest updates, insights, and news on all things simpcity!